105 Delhi Rd, North Ryde

NSW 2113

Expertise perfected over time

Our capabilities are built upon the institutional knowledge and individual experiences gained through decades spent developing advanced instrumentation for astronomy.

We have delivered over 100 projects encompassing a broad engineering skill base, using technologies including:

- bulk optics

- micro-optics

- fibre-optics

- photonics

- optomechanics

- mechatronics and control systems

- sensors and detectors

- cryogenics

- software control systems

- data management.

We employ both phased (waterfall) and incremental (Agile) project management methodologies in our scientific, research, and technical projects. We're also adept at:

- risk analysis and mitigation management

- financial and resource forecasting, monitoring, and reporting

- product and quality assurance.

Our rigorous systems engineering approach ensures our systems are 'fit for purpose' and 'right the first time'. We utilise:

- model-based system engineering practices

- requirements analysis, verification, and validation

- approach projects from a holistic and interdisciplinary perspective.

AAO-Macquarie develops and maintains Data Central, which is an e-research platform and data archive that facilitates cutting-edge science. Data Central provides web-based tools and archive functionality for scientists from a range of disciplines. It allows users to:

- explore, access and manage data

- collaborate through wikis, cloud storage and a teams portal

- publish new discoveries and data.

With a long history of experience in optical and radio astronomy software and algorithm design and development, the AAO-Macquarie software team specialises in:

- instrument and telescope control

- middleware providing a fast, distributed and stable platform for control applications

- astronomical data reduction software and algorithms.

Our key areas of work

Design and development of:

- bespoke software solutions for research teams

- astronomical data reduction algorithms and software

- astronomical instrumentation control software

- astronomical instrumentation user software.

We also provide:

- support for the astronomical community’s data reduction needs

- provision of expert consulting services for astronomical software and deployment applications.

Using professional ray-tracing optical design and scattered-light analysis software (such as Zemax and FRED), our optical engineering team can design complex spectrographs, optical cameras and other optical systems operating at wavelengths from the UV to the near-infrared.

We have laboratories and clean rooms that are dedicated to optical system component testing and verification that have optics, photometric, and interferometric metrology equipment and diffraction grating characterisation rigs.

Our facilities are equipped with micron-scale alignment systems, alignment scopes, and calibration sources and detectors, for the assembly, alignment, integration, and testing of complex optical subsystems.

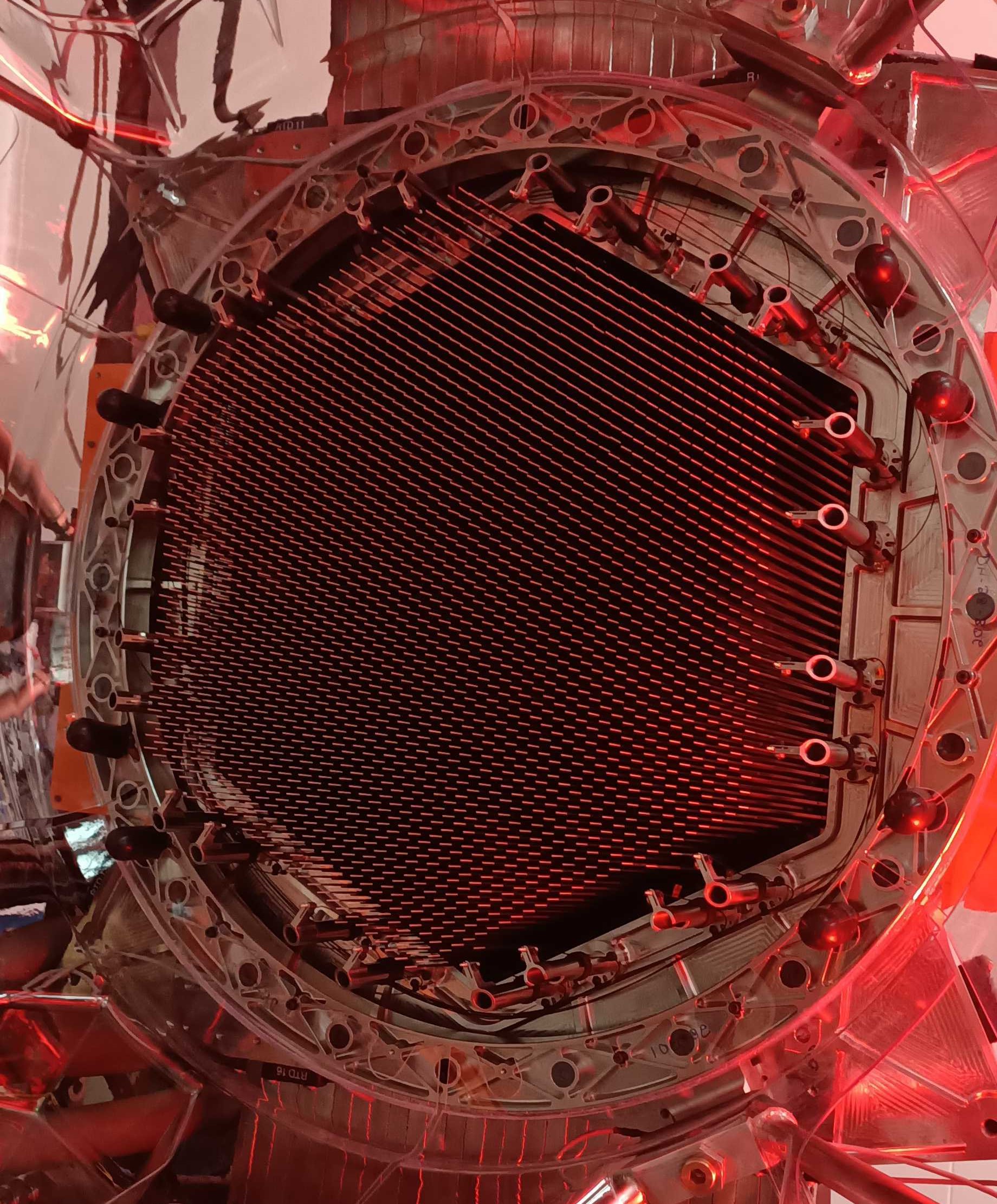

Our expertise in optical fibres extends across characterisation, polishing, cabling, and connectorisation, for single-fibre to thousand-fibre bundles. We have the necessary skills and techniques for accurate bonding of micro-optics to fibre bundles with micron-scale precision.

We have a large mechanical engineering group with expertise across a number of areas. Our design experience includes:

- mechanical conceptual design and development

- mechatronic design

- optomechanical mounting design

- cryogenics design

- pneumatic systems

- hydraulic systems

- detector development

We use a range of 3D modelling tools such as Autodesk Inventor and have substantial experience in vibration and earthquake analysis, heat transfer modelling, finite element analysis, and failure modes and effect analysis.

Our state-of-the-art mechanical workshop is capable of fabricating high-precision components. This includes milling, lathing and computer numerical control (CNC) tools and machines.

For assembly, we have experience in designing and developing custom jigs, fixtures, and tooling, and have precision metrology equipment such as coordinate measuring machines.

We design electronic and electrical systems for controlling instrumentation and detectors. These systems include printed circuit boards, enclosures and cabling.

Our designs are based on the analysis of the requirements for the project and include the evaluation of suitable technologies to achieve a low-risk solution. We use commercial off-the-shelf components or undertake custom PCB designs where required.

We have experience in analog and digital electronics, micro-controller and DSP development (including firmware), motion control systems and PLCs.

Our designs use standardised communications systems including Ethernet and industrial fieldbuses. We use many design tools, including Altium CAD software.

We build many types of electrical and electronic systems including printed circuit boards, enclosures, and cables. We can assemble rigid and flexible PCBs using surface mount technology and through-hole components.

We can build and wire up chassis and other enclosures from custom PCBs as well as commercial off-the-shelf components.

We undertake in-house manufacture of cable assemblies, using a variety of different types of connector technology.

We perform circuit board, chassis-level and system-level integration, testing and debugging. Our electronics laboratory is well resourced with all the standard tools and equipment needed to support these activities.

In consultation with our clients, we develop integration and test plans for all our projects in the early design stages to guarantee their successful development.

We have dedicated assembly clean-rooms and laboratories to cover these full integration and final test phases of instrument projects, where all the required multi-disciplinary components and teams are brought together.